- Our location

- sitemap

- E-mail : sales@daiwomining.com

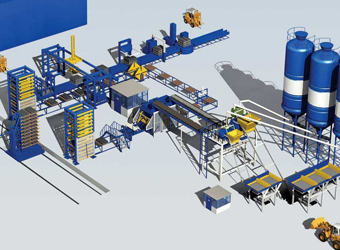

Simple Brick Making Production Line

Simple Brick Making Production Line

Simple Brick Making Production Line is mainly a mixer, conveyor and makes a small unit, also can the conveyor, directly by using artificial feeding, cloth, mainly based on the local market and the demand of production to choose baking-free brick machine.

1.The main equipment parts

From the most simple configuration to the automatic production line, we may, according to the actual situation of the users provide various types, Production equipment and to help customers complete plant process design.

1. The main scope of supply includes:(JS500 JS750 JS1000)

2. Equipment (a) forced mixer (JS500 JS750 JS1000)

3. block molding machine Pallet Conveyor ,Send brick machine,Lateral mention the trigger,The electric control system and hydraulic system

4. trigger automatic promotion

5. secondary fabric device

2. Supporting parts

(1) ask board molding 2000-3000 a (customer Buy their own)

(2)the cement warehouse fly ash warehouse (option )

(3) automatic batching system (option)

(4)screw conveyor (option)

(5)cement metering system (optional)

(6)water metering system (optional)

3. the requirements of raw materials

Equipment for raw materials has a good adaptability, and taking into account the requirements of the fly ash and other industrial residues as raw materials:

(1) Cement: shall comply with the provisions of GB 175, GB / T 2015.

(2) Fine Aggregate: shall comply with the provisions of GB / T 14 684

(3) Coarse aggregate: crushed stone, gravel should be consistent with the provisions of GB / T 14685, heavy slag shall comply with the provisions of YBJ 20 584. Bottom slag and ash mixed, 0.16mm sieve the rest of the loss on ignition shall not be in the 15%. Stone chips: less than 0.16mm fine dust content should not exceed 20%.

(4) Admixtures: Fly ash shall comply with the provisions of GB / T 1596 and GB 6566, blast furnace slag shall comply with the provisions of GB / T 18 046.

(5) lightweight aggregate: shall comply with the provisions of GB / T 17 431.

(6) admixture: shall comply with the provisions of GB of 8 076 and JC 474.

(7) Pigments: shall comply with the provisions of JC / T 539

(8) Water: should be consistent with JGJ 63

|

NO. |

Name |

Model |

Quantity |

Remarks |

|

1 |

Condominium shaft mixer |

JS750 |

1 |

option |

|

2 |

brick machine |

|

1 |

|

|

3 |

Liquid pump station |

Random supporting |

1 |

|

|

4 |

Conveyor belt I |

Random supporting |

1 |

|

|

5 |

Pallet Conveyor |

Random supporting |

1 |

|

|

6 |

Send brick machine |

Random supporting |

1 |

------ |

|

7 |

Computer control cabinet |

Random supporting |

1 |

Random supporting |

|

8 |

mould |

Random supporting |

1 |

|

|

9 |

Automatic and fabric system |

|

1 |

|

|

10 |

Fabric conveyor belt II |

|

1 |

|

|

11 |

Fabric mixer |

JQM500 |

1 |

|

|

12 |

Automatic brick machine code |

|

1 |

|

|

13 |

Hydraulic strollers |

|

1 |

option |

|

14 |

Bamboo veneer |

1100×680×25mm |

1 |

|

|

15 |

Fabric mixer |

JQM500 |

1 |

|

|

16 |

Automatic brick machine code |

|

1 |

|

|

17 |

Hydraulic strollers |

|

2 |

|

|

18 |

pallet |

|

2000 |

|