- Our location

- sitemap

- E-mail : sales@daiwomining.com

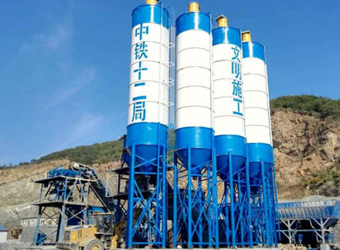

Cement Warehouse (Cement Tank)

Cement Warehouse (Cement Tank)

Cement silo is suit for storage of cement, fly ash and other bulk materials, the tank is equipped with a material system which can display the position of the material.

Structure and composition:

Cement silo (cement tank)is cylindrical structure, the bottom of the four tube legs support the position whole body , the entire warehouse is all the steel form and welded;upper apex is equipped with Dust catcher and pressure relief valve; composition: position steel body parts, ladder, guard rails, feeding tubes, dust collector, pressure relief valve, high and low level meter, the discharge valve. Working principle:

1. When the cement silo work,The special crane must be the stand, And then on the basis of concrete prefabricated good in advance and check the cement silo erected after the vertical with the horizontal, and then the bottom and the basis of pre-embedded parts firm.

2. After fixed.By bulk cement car shipping cement to the construction site, and then Connect transfer pipe line of cement truck With Cement warehouse the feed of the pipeline. Through Bulk cement car of gas pressure taking Tank conveyed to the cement warehouse in cement

3. in the process of conveying the cement storage silos, the operator continuous button pressing the precipitator vibration motor, and shake off the cement attached to the Filter bag. prevent blocked bag, and Blasting warehouse

4. Once blocked the bag, The pressure in the storehouse more than safety pressure of Warehouse top pressure relief valve . the pressure safety relief valve can open release the pressure in the warehouse, prevent explosion warehouse accidents.

5. Warehouse full and starving can be observed Through the high and low material place

6. When the discharge is required, first open the cone at the bottom of the manual discharge valve, and then through the cement delivery device (screw conveyor) cement transfer out. In the process of discharge, if there is "bagging" phenomenon, timely press the button of the arch breaker solenoid valve, blow and eliminate the "bagging" the feed, to ensure smooth supply of cement.

7. When the failure of the cement delivery device (screw conveyor), first turn off the cone at the bottom of the manual discharge valve to prevent the cement spill, resulting in waste.

The specification: Discharge height are 1.96 meters, 4.2 meters, can also manufacture according to user requirements; capacity are 30t, 50t, 60t, 80t, 100t, 200t, 300t, 500t and so on.

|

Cement warehouse model |

Tank diameter |

Tanks height |

the total height of tank |

Match host |

With the screw conveyor |

|

JLSNC 30T |

2.5m |

4.8m |

11.4m |

JDC350 |

LSY 163 (type) |

|

JLSNC 50T |

3m |

5.4m |

12m |

JS500 |

LSY 180 (type) |

|

JLSNC 80T |

3m |

9m |

15.6m |

JS750 |

LSY 180 (type) |

|

JLSNC 100T |

3m |

11.4m |

18m |

JS1000 |

LSY 230 (type) |

|

JLSNC 150T |

3m |

23.5m |

29m |

JS1000 |

LSY 230 |

|

JLSNC 200T |

4.5m |

18.6m |

25.2m |

JS1500 |

LSY 230 |

|

JLSNC 300T |

4.5m |

24.6m |

29.5m |

JS2000 |

LSY 230 |

|

JLSNC 500T |

6m |

22.2m |

28.8m |

JS3000 |

LSY 230 |